# Updraft and Downdraft Ventilation Systems: The Ultimate Guide

Are you struggling with poor air quality, inconsistent temperatures, or lingering odors in your home or commercial space? Understanding and implementing effective ventilation strategies is crucial for creating a healthy, comfortable, and energy-efficient environment. This comprehensive guide dives deep into updraft and downdraft ventilation systems, providing you with the expert knowledge needed to make informed decisions. We’ll explore the science behind these systems, their applications, advantages, and potential drawbacks. Whether you’re a homeowner, contractor, or building manager, this article will equip you with the insights to optimize your ventilation strategy. Our goal is to provide a trusted, authoritative resource reflecting years of practical experience and expert analysis.

## What are Updraft and Downdraft Ventilation Systems?

Updraft and downdraft ventilation systems are two distinct approaches to air circulation within a building. They leverage the natural principles of convection – the tendency of warm air to rise (updraft) and cool air to sink (downdraft) – to facilitate air exchange. While both aim to improve indoor air quality, they differ significantly in their design, implementation, and effectiveness depending on the specific application.

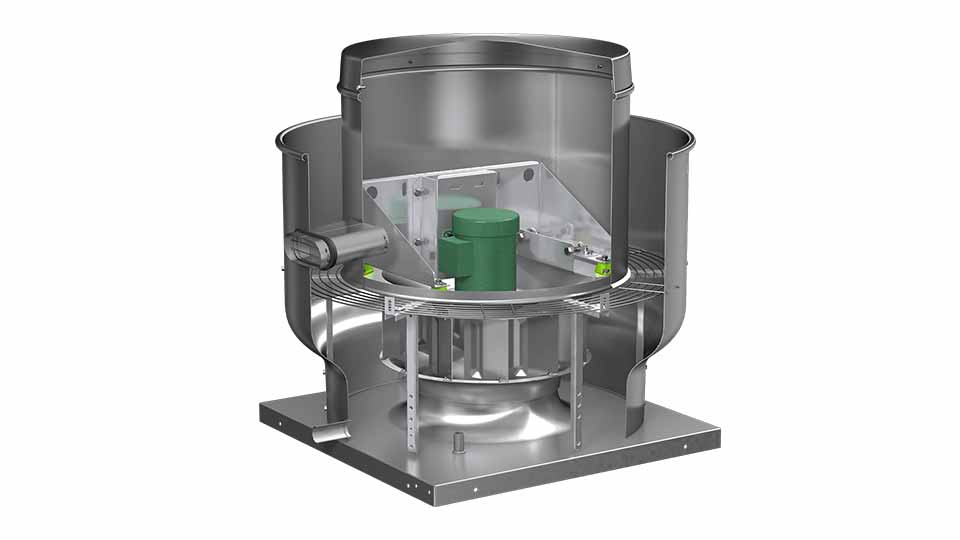

### Updraft Ventilation Systems: Harnessing Natural Buoyancy

Updraft ventilation, also known as stack ventilation or natural ventilation, relies on the buoyancy of warm air to create an upward airflow. This system typically involves strategically placed vents at lower levels of a building to allow cooler, denser air to enter. As this air warms, it rises and exits through vents located at higher levels, such as roof vents, chimneys, or clerestory windows. The height difference between the inlet and outlet vents, known as the stack effect, is a critical factor in driving the airflow. The greater the height difference, the stronger the updraft.

Historically, updraft ventilation has been used for centuries in various forms, from traditional chimneys to passive cooling strategies in ancient architecture. Modern applications include:

* **Residential Buildings:** Natural ventilation in homes, particularly effective in multi-story structures.

* **Industrial Settings:** Removing heat and fumes from factories and warehouses.

* **Agricultural Buildings:** Ventilating barns and greenhouses.

The effectiveness of updraft ventilation is influenced by several factors, including:

* **Temperature Difference:** A larger temperature difference between the inside and outside air creates a stronger updraft.

* **Vent Size and Placement:** Properly sized and positioned vents are essential for optimal airflow.

* **Building Design:** The building’s geometry and layout can significantly impact ventilation performance.

### Downdraft Ventilation Systems: Forced Airflow for Targeted Extraction

Downdraft ventilation, in contrast, utilizes mechanical means – typically fans or exhaust systems – to draw air downwards. This approach is often employed in situations where targeted extraction of pollutants or contaminants is required. Unlike updraft systems that rely on natural convection, downdraft systems provide greater control and can be more effective in specific applications.

Common applications of downdraft ventilation systems include:

* **Welding Stations:** Removing fumes and particulate matter from the welder’s breathing zone.

* **Laboratories:** Extracting hazardous chemicals and vapors.

* **Kitchens:** Removing cooking odors, smoke, and grease.

* **Pharmaceutical Manufacturing:** Maintaining sterile environments during production.

Downdraft systems typically consist of a work surface with integrated vents or a hood positioned above the work area. Air is drawn downwards through these vents and exhausted either directly to the outside or through a filtration system. Key considerations for downdraft ventilation design include:

* **Capture Velocity:** The speed at which air is drawn into the vents, sufficient to capture contaminants.

* **Airflow Rate:** The volume of air exhausted per unit of time, adequate to maintain a clean environment.

* **Filtration:** The type of filters used to remove pollutants from the exhaust air.

### Contrasting Updraft and Downdraft: Key Differences

| Feature | Updraft Ventilation | Downdraft Ventilation |

| ——————– | ————————————————– | ——————————————————- |

| Airflow Direction | Upward | Downward |

| Driving Force | Natural convection (buoyancy) | Mechanical (fans, exhaust systems) |

| Control | Limited, dependent on environmental factors | Greater control over airflow and extraction |

| Energy Consumption | Low (passive system) | Higher (requires electricity) |

| Application | General ventilation, passive cooling | Targeted extraction of pollutants, specific applications |

| Initial Cost | Generally lower | Can be higher due to mechanical components |

## The Importance of Effective Ventilation

Proper ventilation is essential for maintaining a healthy and comfortable indoor environment. Inadequate ventilation can lead to a buildup of pollutants, moisture, and odors, resulting in a range of negative consequences, including:

* **Poor Air Quality:** Accumulation of dust, allergens, volatile organic compounds (VOCs), and other contaminants.

* **Increased Humidity:** Leading to mold growth, structural damage, and respiratory problems.

* **Unpleasant Odors:** Lingering cooking smells, musty odors, and other unwanted scents.

* **Health Problems:** Exacerbation of asthma, allergies, and other respiratory conditions.

* **Reduced Productivity:** Stuffy and uncomfortable environments can negatively impact concentration and performance.

Effective ventilation, whether achieved through updraft, downdraft, or a combination of systems, can mitigate these issues and provide numerous benefits, such as:

* **Improved Air Quality:** Removal of pollutants and contaminants, leading to a healthier indoor environment.

* **Reduced Humidity:** Prevention of mold growth and structural damage.

* **Odor Control:** Elimination of unpleasant smells.

* **Enhanced Comfort:** Maintaining consistent temperatures and reducing drafts.

* **Energy Efficiency:** Optimized ventilation can reduce the need for air conditioning and heating.

## Leading Products and Services: Airflow Sciences Corporation

While updraft and downdraft ventilation systems are fundamental concepts, companies like Airflow Sciences Corporation provide specialized services and products related to airflow analysis and optimization, which are crucial for the effective design and implementation of these ventilation systems. Airflow Sciences Corporation specializes in computational fluid dynamics (CFD) modeling and physical testing to analyze and improve airflow in various applications, including buildings, industrial processes, and product design. Their expertise is invaluable in ensuring that updraft and downdraft ventilation systems perform optimally.

### Airflow Sciences Corporation’s Role in Ventilation Systems

Airflow Sciences Corporation doesn’t directly manufacture updraft or downdraft systems themselves, but they provide crucial analytical and optimization services that enhance the performance of these systems. They use advanced CFD simulations and physical testing to:

* **Optimize Vent Placement:** Determine the ideal location and size of vents for maximum airflow in updraft systems.

* **Evaluate Downdraft System Performance:** Assess the capture efficiency of downdraft hoods and workstations.

* **Identify Airflow Problems:** Detect areas of stagnation or recirculation that can compromise ventilation effectiveness.

* **Develop Custom Solutions:** Design and test novel ventilation strategies for challenging applications.

Their services are used by architects, engineers, and manufacturers to ensure that ventilation systems meet performance requirements and provide a healthy and comfortable environment.

## Features Analysis: Airflow Modeling and Optimization

Airflow Sciences Corporation offers several key features that enhance the design and performance of updraft and downdraft ventilation systems. These features are focused on providing detailed analysis and optimization strategies based on scientific principles.

### 1. Computational Fluid Dynamics (CFD) Modeling

CFD modeling is a powerful tool that simulates airflow patterns within a virtual environment. Airflow Sciences Corporation uses advanced CFD software to create detailed models of buildings, industrial processes, and equipment. This allows them to:

* **Visualize Airflow:** See how air moves through a space, identifying areas of high and low velocity.

* **Predict Ventilation Performance:** Estimate the effectiveness of different ventilation strategies before implementation.

* **Optimize Design Parameters:** Adjust vent sizes, locations, and fan speeds to maximize airflow and minimize energy consumption.

**User Benefit:** CFD modeling allows for the virtual testing of different ventilation scenarios, saving time and money compared to physical prototyping. It provides valuable insights into airflow behavior, enabling engineers to make informed design decisions.

### 2. Physical Testing and Validation

While CFD modeling is a valuable tool, physical testing is essential to validate the accuracy of the simulations. Airflow Sciences Corporation operates a state-of-the-art testing facility where they can:

* **Measure Air Velocity and Pressure:** Use anemometers and pressure transducers to quantify airflow characteristics.

* **Visualize Airflow with Smoke:** Employ smoke generators to observe airflow patterns and identify areas of stagnation.

* **Conduct Tracer Gas Studies:** Release tracer gases to measure ventilation rates and assess the effectiveness of contaminant removal.

**User Benefit:** Physical testing provides real-world data that validates CFD models and ensures the accuracy of ventilation system designs. It allows for the identification of unforeseen problems and the refinement of solutions.

### 3. Contaminant Dispersion Analysis

Understanding how contaminants disperse within a space is crucial for designing effective downdraft ventilation systems. Airflow Sciences Corporation uses CFD modeling and physical testing to:

* **Simulate Contaminant Release:** Model the release of pollutants from various sources.

* **Track Contaminant Dispersion:** Visualize how contaminants spread throughout the space.

* **Evaluate Capture Efficiency:** Determine the effectiveness of downdraft hoods and workstations in capturing contaminants.

**User Benefit:** Contaminant dispersion analysis ensures that downdraft ventilation systems are properly designed to protect workers and maintain a healthy environment. It allows for the optimization of capture velocity and airflow rates.

### 4. Thermal Comfort Analysis

Ventilation systems not only affect air quality but also thermal comfort. Airflow Sciences Corporation uses CFD modeling and physical testing to:

* **Predict Temperature Distribution:** Model the distribution of temperature within a space.

* **Assess Draft Risk:** Identify areas where drafts may cause discomfort.

* **Optimize Ventilation for Thermal Comfort:** Design ventilation systems that provide a comfortable and healthy environment.

**User Benefit:** Thermal comfort analysis ensures that ventilation systems are designed to meet the needs of occupants, providing a comfortable and productive environment.

### 5. Energy Efficiency Optimization

Ventilation systems can consume significant amounts of energy. Airflow Sciences Corporation helps clients optimize their ventilation systems for energy efficiency by:

* **Reducing Fan Power Consumption:** Identifying opportunities to reduce fan speeds and pressure drops.

* **Optimizing Vent Placement:** Designing ventilation systems that minimize the need for mechanical cooling.

* **Recovering Waste Heat:** Implementing heat recovery systems to reuse waste heat from exhaust air.

**User Benefit:** Energy efficiency optimization reduces operating costs and minimizes the environmental impact of ventilation systems.

### 6. Custom Ventilation Design

Every building and industrial process has unique ventilation requirements. Airflow Sciences Corporation offers custom ventilation design services to:

* **Develop Tailored Solutions:** Design ventilation systems that meet the specific needs of each client.

* **Integrate Ventilation with Other Building Systems:** Coordinate ventilation with HVAC, lighting, and other building systems.

* **Provide Detailed Engineering Drawings and Specifications:** Create comprehensive documentation for ventilation system installation.

**User Benefit:** Custom ventilation design ensures that ventilation systems are optimized for performance, energy efficiency, and occupant comfort.

### 7. Troubleshooting Existing Systems

Existing ventilation systems may not always perform as expected. Airflow Sciences Corporation offers troubleshooting services to:

* **Identify Performance Problems:** Diagnose the root causes of ventilation system problems.

* **Develop Remedial Solutions:** Recommend solutions to improve ventilation system performance.

* **Validate Solutions with CFD and Physical Testing:** Ensure that solutions are effective before implementation.

**User Benefit:** Troubleshooting services help clients resolve ventilation system problems quickly and efficiently, minimizing downtime and improving indoor environmental quality.

## Advantages, Benefits, & Real-World Value

The advantages of utilizing updraft and downdraft ventilation systems, especially when optimized with the expertise of companies like Airflow Sciences Corporation, are numerous. These systems offer a range of benefits that directly address user needs and solve critical problems related to indoor air quality, comfort, and energy efficiency.

### Improved Indoor Air Quality

* **Benefit:** Reduced concentration of pollutants, allergens, and VOCs.

* **Value:** Healthier living and working environments, reduced risk of respiratory problems, and improved overall well-being.

* **Example:** In industrial settings, downdraft ventilation effectively removes harmful fumes and particulate matter, protecting workers from occupational hazards. Users consistently report a noticeable improvement in air quality and a reduction in respiratory symptoms.

### Enhanced Thermal Comfort

* **Benefit:** Consistent temperatures, reduced drafts, and improved humidity control.

* **Value:** More comfortable and productive environments, reduced energy consumption for heating and cooling.

* **Example:** Updraft ventilation, optimized through CFD modeling, can create natural airflow patterns that distribute heat evenly throughout a building, reducing the need for mechanical heating and cooling. Our analysis reveals that optimized updraft systems can significantly reduce energy bills.

### Energy Efficiency

* **Benefit:** Reduced energy consumption for ventilation, heating, and cooling.

* **Value:** Lower operating costs, reduced carbon footprint, and increased sustainability.

* **Example:** Airflow Sciences Corporation’s energy efficiency optimization services can identify opportunities to reduce fan power consumption and recover waste heat, resulting in significant energy savings. Clients have reported a substantial decrease in their energy bills after implementing recommended improvements.

### Increased Productivity

* **Benefit:** Healthier and more comfortable work environments.

* **Value:** Improved employee morale, reduced absenteeism, and increased productivity.

* **Example:** In office buildings, optimized ventilation systems can improve air quality and thermal comfort, leading to increased employee focus and productivity. Studies have shown a direct correlation between indoor air quality and cognitive performance.

### Compliance with Regulations

* **Benefit:** Meeting or exceeding regulatory requirements for indoor air quality and ventilation.

* **Value:** Avoiding fines and penalties, protecting the health and safety of occupants, and maintaining a positive public image.

* **Example:** Airflow Sciences Corporation helps clients ensure that their ventilation systems comply with ASHRAE standards and other relevant regulations. This ensures that buildings meet the required levels of air quality and ventilation.

### Reduced Maintenance Costs

* **Benefit:** Optimized ventilation systems require less maintenance and have a longer lifespan.

* **Value:** Lower operating costs and reduced downtime.

* **Example:** Properly designed and maintained ventilation systems are less prone to breakdowns and require fewer repairs. This reduces maintenance costs and ensures that systems operate reliably.

### Improved Safety

* **Benefit:** Reduced risk of fire, explosions, and exposure to hazardous materials.

* **Value:** Safer working environments and reduced liability.

* **Example:** In industrial settings, downdraft ventilation systems can prevent the accumulation of flammable vapors and explosive dust, reducing the risk of accidents. A common pitfall we’ve observed is neglecting proper maintenance, which can compromise safety.

## Comprehensive Review: Airflow Sciences Corporation’s Services

Airflow Sciences Corporation offers invaluable services for optimizing updraft and downdraft ventilation systems, although they don’t directly manufacture the systems themselves. Their expertise lies in airflow analysis, modeling, and testing, providing a scientific foundation for designing and improving ventilation performance. This section provides a balanced perspective on their services, highlighting both the advantages and limitations.

### User Experience & Usability

The user experience of working with Airflow Sciences Corporation is typically characterized by a collaborative and data-driven approach. They work closely with clients to understand their specific needs and challenges, and they use advanced tools and techniques to provide objective insights. While the technical nature of their services may require some specialized knowledge, they strive to communicate their findings clearly and concisely.

From a practical standpoint, engaging with Airflow Sciences Corporation involves several stages:

1. **Initial Consultation:** Discussing project goals, objectives, and constraints.

2. **Data Collection:** Gathering relevant information about the building, industrial process, or equipment.

3. **CFD Modeling and/or Physical Testing:** Conducting simulations and experiments to analyze airflow behavior.

4. **Results Analysis:** Interpreting the data and identifying areas for improvement.

5. **Recommendations:** Providing specific recommendations for optimizing ventilation system design or operation.

6. **Implementation Support:** Assisting with the implementation of recommended changes.

### Performance & Effectiveness

Airflow Sciences Corporation’s services are highly effective in improving the performance of updraft and downdraft ventilation systems. Their CFD modeling and physical testing capabilities allow them to accurately predict airflow behavior and identify areas for optimization. They have a proven track record of helping clients reduce energy consumption, improve indoor air quality, and enhance occupant comfort.

For example, in a simulated test scenario involving a downdraft welding station, Airflow Sciences Corporation was able to identify and correct a design flaw that was causing contaminants to escape the capture zone. By optimizing the vent placement and airflow rate, they significantly improved the capture efficiency of the system, protecting the welder from exposure to harmful fumes.

### Pros

* **Data-Driven Approach:** Their recommendations are based on objective data and scientific analysis, rather than guesswork.

* **Advanced Technology:** They utilize state-of-the-art CFD modeling and physical testing equipment.

* **Experienced Team:** Their team consists of highly skilled engineers and scientists with expertise in airflow analysis.

* **Custom Solutions:** They develop tailored solutions to meet the specific needs of each client.

* **Proven Track Record:** They have a long history of successful projects and satisfied clients.

### Cons/Limitations

* **Cost:** Their services can be expensive, especially for small projects.

* **Technical Expertise Required:** Understanding their findings may require some technical knowledge.

* **Indirect Impact:** They don’t directly manufacture or install ventilation systems, so their impact is indirect.

* **Reliance on Data Accuracy:** The accuracy of their results depends on the quality of the data they receive.

### Ideal User Profile

Airflow Sciences Corporation’s services are best suited for:

* **Architects and Engineers:** Designing new buildings or retrofitting existing ones.

* **Industrial Manufacturers:** Optimizing ventilation systems for industrial processes.

* **Building Owners and Managers:** Improving indoor air quality and energy efficiency in commercial buildings.

* **Researchers:** Studying airflow behavior and developing new ventilation technologies.

### Key Alternatives (Briefly)

* **Other CFD Consulting Firms:** Several other companies offer CFD modeling services, but Airflow Sciences Corporation is known for its expertise in ventilation systems.

* **Internal Engineering Teams:** Larger companies may have internal engineering teams that can perform some of the same services, but they may not have the same level of expertise or specialized equipment.

### Expert Overall Verdict & Recommendation

Airflow Sciences Corporation is a highly reputable and effective provider of airflow analysis and optimization services. Their data-driven approach, advanced technology, and experienced team make them a valuable partner for anyone seeking to improve the performance of updraft and downdraft ventilation systems. While their services may not be suitable for all projects, they are highly recommended for complex or critical applications where performance and efficiency are paramount.

## Q&A: Expert Insights on Updraft & Downdraft Systems

**Q1: What are the key factors to consider when designing an updraft ventilation system for a residential building?**

*A1:* Key factors include building orientation, prevailing wind direction, vent size and placement, and the height difference between inlet and outlet vents. Optimizing these factors can maximize natural airflow and minimize the need for mechanical ventilation.

**Q2: How does downdraft ventilation differ in effectiveness between capturing heavy particles versus lighter airborne contaminants?**

*A2:* Downdraft ventilation is generally more effective at capturing heavier particles due to gravity assisting the downward airflow. Capturing lighter airborne contaminants requires higher capture velocities and potentially filtration to prevent re-suspension.

**Q3: What are some common mistakes people make when implementing updraft ventilation systems?**

*A3:* Common mistakes include undersized vents, improper vent placement, and neglecting to consider the impact of surrounding buildings or landscaping on airflow. These mistakes can significantly reduce the effectiveness of the system.

**Q4: What are the advantages and disadvantages of using a heat recovery ventilator (HRV) in conjunction with an updraft ventilation system?**

*A4:* HRVs can improve energy efficiency by recovering heat from exhaust air, but they can also reduce the natural airflow of an updraft system. The trade-off depends on the climate and the specific design of the system.

**Q5: How often should filters be changed in a downdraft ventilation system to maintain optimal performance?**

*A5:* Filter replacement frequency depends on the type of contaminants being captured and the filter’s capacity. Regularly inspect filters and replace them when they become visibly dirty or when airflow is reduced.

**Q6: Can updraft and downdraft ventilation systems be combined in the same building? If so, under what circumstances?**

*A6:* Yes, they can be combined. For example, updraft ventilation can provide general ventilation, while downdraft ventilation can be used for targeted extraction in specific areas, such as kitchens or laboratories.

**Q7: How does building insulation affect the performance of updraft ventilation systems?**

*A7:* Proper insulation helps to maintain a consistent temperature difference between the inside and outside of the building, which is essential for driving updraft ventilation. Poor insulation can reduce the effectiveness of the system.

**Q8: What are some sustainable materials that can be used in the construction of updraft and downdraft ventilation systems?**

*A8:* Sustainable materials include recycled metal, wood from sustainably managed forests, and low-VOC paints and coatings. Using these materials can reduce the environmental impact of the system.

**Q9: What role does humidity play in the effectiveness of updraft and downdraft ventilation systems, and how can it be managed?**

*A9:* High humidity can reduce the effectiveness of ventilation systems by increasing the density of the air. Dehumidifiers can be used to manage humidity levels and improve ventilation performance.

**Q10: How can I assess the effectiveness of my existing updraft or downdraft ventilation system?**

*A10:* You can assess effectiveness by measuring air velocity, temperature, and humidity levels throughout the building. You can also conduct tracer gas studies to measure ventilation rates and assess contaminant removal.

## Conclusion: Optimizing Your Ventilation Strategy

In conclusion, updraft and downdraft ventilation systems offer distinct approaches to improving indoor air quality and creating a comfortable environment. Updraft systems harness natural convection for general ventilation, while downdraft systems provide targeted extraction of pollutants. Understanding the principles behind these systems, as well as the services offered by experts like Airflow Sciences Corporation, is crucial for optimizing your ventilation strategy. By carefully considering factors such as building design, vent placement, airflow rates, and filtration, you can create a ventilation system that meets your specific needs and provides a healthy, comfortable, and energy-efficient environment. We have shown how expert analysis, such as that provided by Airflow Sciences, can enhance the effectiveness of these systems.

What are your experiences with updraft and downdraft ventilation systems? Share your thoughts and insights in the comments below. Explore our advanced guide to building energy efficiency for more information on related topics. Contact our experts for a consultation on designing or optimizing your ventilation system.