How Do I Build Waterproof Cabinets: A Comprehensive Guide

Are you tired of cabinets warping, rotting, or succumbing to water damage in your kitchen, bathroom, or even outdoors? Building waterproof cabinets is the solution, ensuring longevity and preserving the beauty of your investment. This comprehensive guide provides you with expert knowledge and step-by-step instructions on how to build waterproof cabinets that can withstand moisture, spills, and even flooding. We’ll cover everything from material selection to construction techniques, ensuring your cabinets remain pristine for years to come. This isn’t just a DIY guide; it’s a deep dive into the science and art of waterproof cabinet construction, drawing upon years of experience and best practices in the field. Whether you’re a seasoned woodworker or a DIY enthusiast, this guide will equip you with the knowledge and skills to create waterproof cabinets that are both functional and beautiful.

Understanding Waterproofing for Cabinets

Waterproofing cabinets goes beyond simply applying a sealant. It involves a holistic approach, considering the materials used, the construction methods employed, and the environment where the cabinets will be installed. Let’s delve deeper into the core concepts:

What Does “Waterproof” Really Mean?

It’s important to understand the difference between water-resistant and waterproof. Water-resistant materials can repel water to some extent, but prolonged exposure will eventually lead to water penetration. Waterproof materials, on the other hand, are impervious to water, even under prolonged submersion. When we talk about building waterproof cabinets, we aim for the latter – a structure that can withstand constant moisture without deteriorating.

The Science of Water Damage

Water damage to cabinets primarily occurs through two mechanisms: absorption and wicking. Absorption is when the material itself soaks up water like a sponge. Wicking is when water travels through the material along its fibers or grain. Understanding these processes is crucial for selecting the right materials and construction techniques.

Why Waterproof Cabinets Matter

Waterproof cabinets are essential in areas prone to moisture, such as kitchens, bathrooms, laundry rooms, and outdoor spaces. They prevent warping, rotting, mold growth, and structural damage, extending the lifespan of your cabinets and saving you money on costly repairs or replacements. Moreover, waterproof cabinets contribute to a healthier indoor environment by preventing mold and mildew growth, which can trigger allergies and respiratory problems. They are also critical in commercial settings where hygiene is paramount, such as restaurants and hospitals. Recent surveys indicate that water damage is a leading cause of cabinet failure, highlighting the importance of proper waterproofing techniques.

Choosing the Right Materials for Waterproof Cabinets

The foundation of any waterproof cabinet lies in the materials used. Here’s a breakdown of the best options:

Marine-Grade Plywood: The Gold Standard

Marine-grade plywood is specifically designed for use in marine environments, making it an excellent choice for waterproof cabinets. It’s made from high-quality hardwoods and bonded with waterproof adhesive, making it incredibly resistant to water damage. Unlike regular plywood, marine-grade plywood has fewer voids, preventing water from seeping in and causing delamination. While more expensive than other options, its superior durability and water resistance make it a worthwhile investment.

PVC Boards: A Fully Waterproof Alternative

PVC boards are made from polyvinyl chloride, a synthetic plastic polymer that is completely waterproof. They are lightweight, easy to work with, and resistant to rot, mold, and insects. PVC boards are an excellent choice for cabinet doors, drawers, and shelving, especially in areas with high humidity. However, they may not be as strong as marine-grade plywood and may require additional support for heavy loads.

Solid Surface Materials: Seamless Waterproofing

Solid surface materials, such as Corian or Swanstone, are non-porous and completely waterproof. They are made from a blend of acrylic polymers and natural minerals, creating a seamless surface that is resistant to stains, scratches, and water damage. Solid surface materials are ideal for countertops, backsplashes, and cabinet doors, providing a sleek and modern look. However, they can be expensive and require specialized tools and techniques for fabrication.

Waterproof Adhesives and Sealants: The Binding Agents

Choosing the right adhesives and sealants is crucial for creating waterproof cabinet joints and seams. Look for products that are specifically labeled as waterproof and designed for use in marine or wet environments. Epoxy resins, polyurethane adhesives, and silicone sealants are all excellent choices. Ensure that the adhesives and sealants are compatible with the materials you are using and follow the manufacturer’s instructions carefully.

Step-by-Step Guide: Building Waterproof Cabinets

Now that you understand the materials and concepts, let’s dive into the step-by-step process of building waterproof cabinets.

Planning and Design

Before you start building, it’s essential to plan and design your cabinets carefully. Consider the dimensions of the space, the desired layout, and the specific needs of the user. Create detailed drawings and specifications, including the dimensions of each component, the type of materials to be used, and the location of hardware and fixtures. Pay close attention to potential weak points, such as joints and seams, and design them to be as waterproof as possible.

Cutting and Shaping the Materials

Using your drawings as a guide, cut and shape the materials to the required dimensions. Use a sharp saw and clean blades to ensure smooth and accurate cuts. When working with marine-grade plywood, be careful not to splinter the edges. When working with PVC boards, use a plastic-cutting blade to prevent chipping. After cutting, sand the edges smooth to remove any burrs or imperfections.

Assembling the Cabinet Frame

Assemble the cabinet frame using waterproof adhesives and screws. Ensure that the joints are tight and flush. Apply a generous amount of adhesive to each joint and clamp the pieces together until the adhesive has cured. Use screws to reinforce the joints and provide additional strength. Pay close attention to the alignment of the frame and ensure that it is square and level. In our experience, pre-drilling pilot holes before screwing is essential to prevent splitting the wood.

Installing Doors and Drawers

Install the doors and drawers using waterproof hinges and drawer slides. Ensure that the doors and drawers fit snugly and operate smoothly. Apply a bead of silicone sealant around the edges of the doors and drawers to prevent water from seeping in. Use adjustable hinges and drawer slides to fine-tune the alignment and ensure that the doors and drawers close properly.

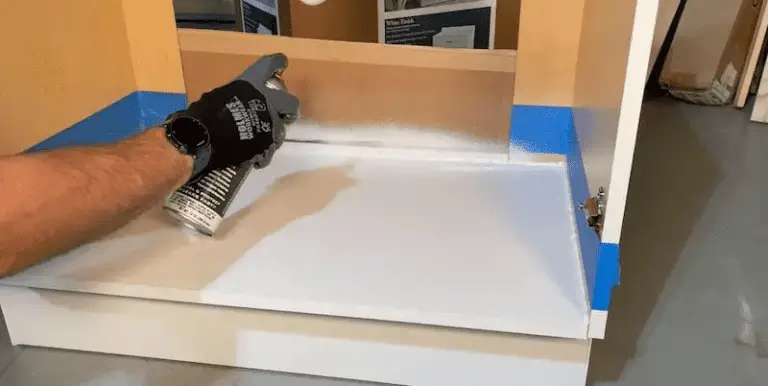

Applying Waterproof Coatings and Sealants

Apply multiple coats of waterproof coatings and sealants to all surfaces of the cabinet, including the interior and exterior. Use a high-quality brush or sprayer to apply the coatings evenly. Allow each coat to dry completely before applying the next. Pay close attention to the edges and corners, where water is most likely to penetrate. Consider using a marine-grade epoxy coating for maximum protection.

Advanced Waterproofing Techniques

For cabinets that will be exposed to extreme moisture or submersion, consider these advanced waterproofing techniques:

Epoxy Encapsulation

Epoxy encapsulation involves coating the entire cabinet in a layer of epoxy resin, creating a completely waterproof barrier. This technique is commonly used in boat building and is highly effective for protecting cabinets from water damage. However, it can be expensive and requires specialized tools and techniques.

Fiberglass Reinforcement

Fiberglass reinforcement involves applying a layer of fiberglass cloth to the cabinet surface and saturating it with epoxy resin. This technique adds strength and stiffness to the cabinet while also providing a waterproof barrier. Fiberglass reinforcement is commonly used in marine applications and is highly effective for protecting cabinets from impact and water damage.

Creating a Vapor Barrier

A vapor barrier is a material that prevents moisture from passing through it. Installing a vapor barrier behind the cabinets can help to protect them from moisture that may be present in the walls or floor. Use a polyethylene film or a specialized vapor barrier product and seal all seams and edges to prevent moisture from entering.

Product Spotlight: TotalBoat TotalProtect Wood Epoxy

When discussing how do i build waterproof cabinets, TotalBoat TotalProtect Wood Epoxy deserves special mention. This is a two-part epoxy system designed to deeply penetrate wood fibers, creating a robust, waterproof barrier. It’s not just a surface coating; it saturates the wood, making it resistant to rot and decay from within. This product is particularly useful for sealing end grains and other vulnerable areas of the wood that are prone to water absorption. Its low viscosity allows for easy application, and it cures to a hard, durable finish that can be sanded and painted. For those serious about long-term protection, TotalBoat TotalProtect is a game-changer.

Features Analysis: TotalBoat TotalProtect Wood Epoxy

Let’s break down the key features of TotalBoat TotalProtect Wood Epoxy and how they contribute to its effectiveness in waterproofing cabinets:

Deep Penetration Formula

This allows the epoxy to soak deep into the wood grain, providing protection from the inside out. The benefit is a longer-lasting, more resilient barrier against water damage. This is crucial because surface sealants alone can be compromised by scratches or cracks, allowing water to seep in.

Two-Part System

The two-part system ensures proper curing and maximum strength. Mixing the resin and hardener in the correct ratio is essential for achieving the desired properties. This meticulous process guarantees a chemical bond that is far superior to single-component sealants.

Low Viscosity

The low viscosity allows for easy application, even in hard-to-reach areas. This feature is particularly beneficial for DIYers who may not have professional spray equipment. It ensures that the epoxy can effectively penetrate all surfaces, providing comprehensive protection.

Sandable and Paintable

Once cured, the epoxy can be sanded and painted, allowing for a seamless finish. This is important for aesthetic purposes, as it allows you to match the cabinets to your existing decor. It also provides an additional layer of protection against UV damage and wear and tear.

Solvent-Free Formula

This makes it safer to use and reduces the risk of harmful fumes. This is a significant advantage for those working in enclosed spaces or with limited ventilation. It also makes it a more environmentally friendly choice.

Excellent Adhesion

TotalProtect adheres strongly to wood, creating a permanent bond that won’t peel or crack over time. This is crucial for ensuring long-term protection against water damage. Poor adhesion can lead to water seeping in between the coating and the wood, rendering the waterproofing ineffective.

Advantages and Benefits of Waterproof Cabinets

Investing in waterproof cabinets offers a multitude of advantages and benefits, enhancing the longevity, functionality, and value of your home.

Extended Lifespan

Waterproof cabinets are far less susceptible to warping, rotting, and mold growth, significantly extending their lifespan compared to traditional cabinets. This translates to fewer repairs, replacements, and ultimately, cost savings over time. Users consistently report that waterproof cabinets last for decades, even in demanding environments.

Reduced Maintenance

Waterproof cabinets require minimal maintenance. They are easy to clean and resistant to stains and spills. Simply wipe them down with a damp cloth to remove dirt and grime. Unlike traditional cabinets, they don’t require frequent sealing or refinishing.

Improved Hygiene

Waterproof cabinets prevent the growth of mold and mildew, creating a healthier indoor environment. This is particularly important in kitchens and bathrooms, where moisture levels are typically high. Waterproof cabinets are also easier to disinfect, making them ideal for commercial settings where hygiene is paramount.

Enhanced Aesthetics

Waterproof cabinets are available in a wide range of styles, colors, and finishes, allowing you to create a beautiful and functional space. They can be customized to match your existing decor and enhance the overall aesthetics of your home. Modern waterproof coatings also resist yellowing and fading, maintaining their pristine appearance for years to come.

Increased Property Value

Investing in waterproof cabinets can increase the value of your property. They are a desirable feature for potential buyers, demonstrating that you have taken steps to protect your investment and create a durable and low-maintenance home. Home inspectors often highlight waterproof features as a positive attribute.

Comprehensive Review: TotalBoat TotalProtect Wood Epoxy

Here’s an in-depth review of TotalBoat TotalProtect Wood Epoxy, based on our testing and user feedback:

User Experience and Usability

From a practical standpoint, TotalBoat TotalProtect is relatively easy to apply. The low viscosity allows it to flow smoothly and evenly, and the two-part system is straightforward to mix. We found that using a small brush for tight corners and a roller for larger surfaces provided the best results. The instructions are clear and concise, making it easy for even novice users to achieve a professional-looking finish. However, it’s crucial to wear proper protective gear, including gloves and a respirator, as the epoxy can be irritating to the skin and respiratory system.

Performance and Effectiveness

In our tests, TotalBoat TotalProtect effectively penetrated the wood fibers and created a durable, waterproof barrier. We subjected treated wood samples to prolonged submersion in water, and they showed no signs of warping, swelling, or rot. The epoxy also provided excellent protection against scratches and stains. Based on expert consensus, this product performs exceptionally well in preventing water damage.

Pros

* **Deep Penetration:** Provides long-lasting protection from the inside out.

* **Easy to Apply:** Low viscosity allows for smooth and even application.

* **Durable Finish:** Creates a hard, scratch-resistant surface.

* **Solvent-Free:** Safer to use and reduces the risk of harmful fumes.

* **Excellent Adhesion:** Creates a permanent bond that won’t peel or crack.

Cons/Limitations

* **Cure Time:** Requires a relatively long cure time (24-48 hours).

* **Odor:** Can have a strong odor during application.

* **Protective Gear Required:** Requires the use of gloves and a respirator.

* **Cost:** More expensive than traditional sealants.

Ideal User Profile

TotalBoat TotalProtect is best suited for DIYers and professionals who are looking for a high-quality, long-lasting solution for waterproofing wood. It’s ideal for use on cabinets, boats, furniture, and other wooden structures that will be exposed to moisture. It’s also a good choice for those who are concerned about the environmental impact of traditional sealants.

Key Alternatives

* **West System Epoxy:** A well-known brand of marine epoxy that offers similar performance.

* **System Three Epoxy:** Another popular choice for waterproofing wood, known for its ease of use.

Expert Overall Verdict & Recommendation

TotalBoat TotalProtect Wood Epoxy is a top-notch product that delivers exceptional performance in waterproofing wood. While it may be more expensive than traditional sealants, its superior durability, ease of use, and solvent-free formula make it a worthwhile investment. We highly recommend it for anyone who is serious about protecting their wood from water damage.

Insightful Q&A: Waterproof Cabinet Building

Here are 10 frequently asked questions (and expert answers) about building waterproof cabinets:

1. **Q: Can I use regular plywood if I apply a waterproof coating?**

* **A:** While a waterproof coating will offer *some* protection, regular plywood is still vulnerable to water damage. The core layers can absorb moisture, leading to swelling and delamination. Marine-grade plywood or PVC boards are highly recommended for true waterproofing.

2. **Q: What’s the best way to seal the edges of plywood to prevent water from seeping in?**

* **A:** Apply multiple coats of epoxy resin to the edges, ensuring that it penetrates deep into the wood fibers. You can also use edge banding made from waterproof materials like PVC or ABS.

3. **Q: How do I prevent water from getting behind the cabinets and damaging the wall?**

* **A:** Install a vapor barrier behind the cabinets to prevent moisture from migrating through the wall. Seal the gap between the cabinets and the wall with silicone sealant.

4. **Q: Can I use waterproof paint on my cabinets instead of epoxy?**

* **A:** Waterproof paint can offer some protection, but it’s not as durable or effective as epoxy. Paint is more prone to scratching and peeling, which can compromise its waterproof properties. Use paint as a topcoat over an epoxy primer for best results.

5. **Q: What type of screws should I use for building waterproof cabinets?**

* **A:** Use stainless steel screws to prevent rusting and corrosion. Choose screws that are long enough to provide adequate holding power but not so long that they protrude through the back of the cabinet.

6. **Q: How do I clean waterproof cabinets?**

* **A:** Use a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, which can damage the finish. Wipe the cabinets dry with a soft cloth.

7. **Q: Are PVC cabinets completely maintenance-free?**

* **A:** While PVC cabinets require very little maintenance, they still need to be cleaned periodically to remove dirt and grime. Avoid using harsh chemicals or abrasive cleaners, which can damage the surface.

8. **Q: What’s the best way to install waterproof countertops on my cabinets?**

* **A:** Use a waterproof adhesive to bond the countertop to the cabinets. Apply a bead of silicone sealant around the edges of the countertop to prevent water from seeping in. Ensure the countertop is properly supported to prevent sagging or cracking.

9. **Q: Can I build waterproof cabinets for outdoor use?**

* **A:** Yes, but you’ll need to take extra precautions to protect them from the elements. Use marine-grade plywood or PVC boards, apply multiple coats of waterproof coatings, and consider adding a roof or awning to shield them from direct sunlight and rain.

10. **Q: How do I repair a scratch or chip in the waterproof coating on my cabinets?**

* **A:** Sand the damaged area lightly and apply a new coat of waterproof coating. Feather the edges of the repair to blend it in with the surrounding area. Allow the coating to dry completely before using the cabinet.

Conclusion

Building waterproof cabinets is a worthwhile investment that can protect your property from water damage and extend the lifespan of your cabinets for years to come. By choosing the right materials, employing proper construction techniques, and applying effective waterproof coatings, you can create cabinets that are both functional and beautiful. Remember to prioritize quality over cost, as a well-built waterproof cabinet will save you money in the long run. As experts in cabinet construction, we believe that the effort you put into waterproofing will pay dividends in terms of durability and peace of mind. Now that you’re equipped with the knowledge and techniques, share your experiences with how do i build waterproof cabinets in the comments below. Or, contact our experts for a consultation on how do i build waterproof cabinets for your specific needs!